Secondary Processing

Hole DrillingFor medical tubing or catheter, hole drilling is to use a drill bit or laser to create precise holes in medical-grade plastic sheets or films. The drill bit or laser removes a tiny sliver of material with each spin or pulse, resulting in a hole that is accurate and consistent in shape and size. The holes can be produced in a variety of shapes, using a variety of applied science advancements. CUUMed offers a wide range of custom hole drilling technologies for you to achieve your requirement.

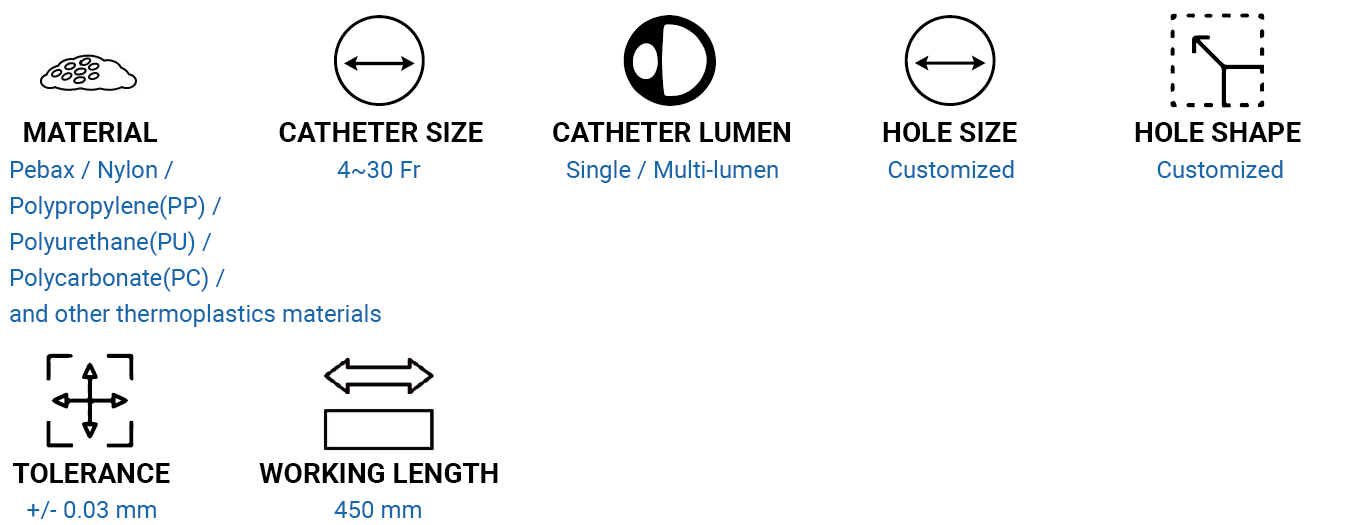

▶ At CUUMed, Catheter hole drilling can create holes with complex shapes and sizes, including oval, square, or rectangular holes. The angle of the hole can also be customized up to 360°, providing greater flexibility in the design of catheter components. Additionally, the catheter hole drilling process is burr-free, ensuring that the resulting holes have a smooth and clean finish.